What is the Best Method of Cannabis Extraction?

In the Science of Extraction, we looked at the need for extraction and the processes surrounding it. We discussed how Valens is doing things differently, and highlighted the need for varying methods of extraction, based on the type of product desired. In this article, instead of asking what’s the best method for extraction, we rather ask: what product are you after? What flavour profiles are you hoping to deliver? What type of experience are your customers looking for?

Valens is the only Canadian cannabis company offering five different types of extraction, with each method offering a variety of end-products. With the ability to select for certain flavours, products, and experiences, we let your destination determine how you get there.

1. Supercritical & Subcritical CO2 Extraction

Carbon Dioxide as a gas is completely natural. We exhale it out every time we breathe, and our plants depend on it to grow. Carbon Dioxide is also the main gas that traps heat in our atmosphere, warming our planet to livable conditions. Without this greenhouse effect, our average temperatures would fall below freezing, and life on earth would cease to exist.

Though this gas is essential, it also carries a bad reputation. As a product of combustion, CO2 is being sent at an unnatural rate into the atmosphere, making it a primary contributor to global warming.

At Valens, we completely recycle all of the CO2 that is used in our cannabis processing, ensuring that our extracts are safe for the consumer and the environment. This level of care has led us to become the first third-party cannabis extraction company in Canada to receive organic certification from Pro-Cert, specifically for our proprietary CO2 and ethanol extraction processing methods.

CO2 in the Industry

Too much carbon dioxide can be hazardous, but without it, we would not have carbonated beverages, dry ice, beer, vitamins, or decaf coffee. As CO2 is used in many industries, quality extraction machinery is able to stay ‘green’ by recapturing all of the gas and using it in subsequent extractions. This allows CO2 to be cost-efficient, easy to obtain, and environmentally friendly. As a solvent, CO2 is also valued for its workplace and consumer safety, as it is non-flammable, non-explosive, and considered safe for ingestion by the FDA.

How it Works – Supercritical CO2

When CO2 is pressurized under high temperature (above 32°C), it becomes a supercritical fluid. These types of solvents possess both gas and liquid properties. As a gas, the solvent can move easily through solids. As a liquid, it can efficiently dissolve compounds into the solution. These properties make supercritical CO2 an optimal solvent for botanical oil extraction.

In cannabis extraction, supercritical CO2 is able to enter into the trichomes, dissolve the cannabinoids and terpenes, and then move them out into the solution. This liquid, now containing the desired extracts and CO2, is then moved into a cyclone separator.

Within the cyclone, pressure and temperature drop to facilitate the movement of CO2 back to the gaseous state. The released gas is then moved into a second separator, where gravity ensures that it is free of residue, as it moves toward the condenser. Here, the gas shifts back into its liquid phase for storage in the accumulator, creating an innovative closed-loop system.

How it Works – Subcritical CO2

Subcritical CO2 still uses CO2 under high pressure, but lowers the temperature to a subcritical state. At this point, the solvent still has some fluid properties, but is not as efficient at extraction. This process is often used to prevent the loss of volatile compounds, with the cost of increased time and reduced yield.

Is it worth it? In many cases, absolutely. These results most closely resemble the starting plant material, offering authentic fragrance and flavour for a full-spectrum product.

Wins and Challenges

The CO2 extraction process can be technical and expensive for low volume runs, but becomes much more cost-efficient on a larger scale. It is becoming one of the most popular extraction methods for bulk processing, well-known for its safety, efficacy, and tunability. High-quality CO2 oil extraction systems (like those at Valens) are closed-loop, allowing for the CO2 to be recycled between extractions. By adjusting the temperature and pressure to move between the two solvent states, carbon dioxide has become one of the most used solvents in the industry.

Best Uses

Supercritical CO2

- Oil (used for capsules and vape pens)

- Waxes

- Shatter

- Concentrates

- Distillates

Subcritical CO2

- Full-flavour oil (closest resemblance to starting material – best for vape pens)

- Terpene extraction

2. Ethanol Extraction

Ethanol is one of the easiest solvents to use and obtain, often dabbled with by the general public in making homemade oil for edibles.

Its simplicity is not lost in the industry, and many professionals prefer ethanol for its universal solvency. With its cost-efficiency, scalability, ease of use, and general safety, ethanol extraction is one of the best methods of extraction.

The Ethanol Advantage

Ethanol’s efficacy can be attributed to its molecular structure, composed of a hydrocarbon tail and a single hydroxyl group. This chemical makeup allows ethanol to dissolve a whole variety of substances, from cannabinoids and terpenes to waxes, lipids, and chlorophyll.

This masterful ability to dissolve may not seem significant, but it allows ethanol to be an efficient solvent. With other solvents like CO2, additional processing is required to remove the waxes, in a process called winterization. However, in ethanol extraction, compounds like cannabinoids and terpenes are pulled directly from the biomass, essentially removing the desired compounds all at once. This provides a winterized oil, but without the crude step that most other solvents require.

Ethanol in the Industry

Ethanol, like CO2, is also generally regarded as safe for consumption by the FDA. It is often found in food preservatives, fruit juices, and alcoholic beverages, and is also considered a certifiably organic solvent in accordance with the Canadian Organic Standards.

How it Works

Ethanol can be used at varying temperatures to have different effects. For example, warm ethanol can be used to quickly wash the plant material, resulting in a full-spectrum concentrate. At cold temperatures, ethanol can be used to produce concentrated distillate, with no additional filtration needed. As high heat is not required for either method, ethanol extraction is well known for producing full-spectrum extracts that closely resemble the starting plant matter in composition.

When Ethanol is ‘Too Good’

One of the main challenges with ethanol is also its powerful dissolving ability. Since it is such a powerful solvent, the first pass through ethanol extraction does not require subsequent winterization. However, ethanol may sometimes also dissolve unwanted compounds into the extract. A good example of this being chlorophyll, which is not harmful if left in the extract, but can impart a green-hue and a grass-like flavour in the end product.Further refinement may be required to remove this compound and increase product purity.

The refinement process ultimately depends on the desired product, again highlighting the need for flexibility in the methods of extraction used. With new advancements in extraction technology and the right people running them, it is becoming possible to by-pass these refinement steps completely.

Environmental Wins

Best Uses

- Oil (used for capsules)

- Tinctures

- Topicals

- Cannabinoids

- Distillates

3. Hydrocarbon Extraction

Hydrocarbon extraction is still one of the most popular methods used for extracting cannabinoids and terpenes. Butane is the most common hydrocarbon solvent used, as it is effective at selectively extracting desired compounds, while also filtering out the unwanted.

Unlike ethanol with its hydroxyl group that can dissolve waxes and chlorophyll, butane is only made up of a hydrocarbon chain. This means that it will dissolve only cannabinoids and terpenes, leaving the rest behind.

Hydrocarbon Challenges

Hydrocarbons are organic solvents that have a bad reputation for being highly flammable and volatile. Many of these solvents have been banned by the FDA and can be toxic even in small concentrations. Though this may sound like a good reason to move right along to the next method, hydrocarbon extraction still has a major place in the industry – it just needs to be done safely and under strict regulation.

Environmental Wins

Butane has a low boiling point, meaning that it is easy to remove from the solution once the extraction is complete. Like our previous two solvents, butane is also generally regarded as safe by the FDA for safe ingestion.

How it Works

The extraction process using hydrocarbon solvents usually involves washing the plant material with cold butane. This slowly dissolves the cannabis and terpenes, leaving behind the rest of the unwanted compounds. Hydrocarbon extraction is famous for the variety of end-products it can produce, with minimal post-processing required.

As high heat is not needed for this extraction, hydrocarbon extraction results in a terpene-rich end product, closely resembling the starting plant material (but without the green pigment). This is also the best extraction method for preserving cannabinoid acids, such as THC-a, which is required for making shatter.

Safety Considerations

The Extraction industry has a reputation for facility explosions, mainly due to improper use of hydrocarbon solvents. Hydrocarbons are very flammable, able to ignite from the simple presence of static electricity. For this reason, regulations have been set out by National Fire Protection Associations and Occupational Safety and Health Administration.

To use these solvents, extraction facilities must house a C1D1 compliant space that has implemented all the required safety measures, such as gas monitoring and zero ignition points. These safety certifications can be difficult to obtain, but they are the only solution for keeping hydrocarbon extraction as a viable option for the industry.

At Valens, we hold multiple licenses for testing and processing cannabis, and we are also fully certified to meet all industry-specific safety requirements. With Health Canada licensing comes regular facility inspections for consumer, workplace, and environmental safety. As a publicly traded company with the goal of progressing our field, Valens is held to the highest standard of safety in all aspects of our business.

Best Uses

- Oil (used for vape pens)

- Concentrates

- Shatter

- Wax

- Butane Hash Oil (BHO)

*all full-spectrum extracts

4. Solventless Extraction

There’s no solvent needed! This is the beauty of solventless extraction, it is safe and inexpensive. Solventless extraction relies on mechanical forces (like pressure) to essentially squeeze out the oils from cannabis. This can be labour-intensive and time consuming, but is still one of the best methods of obtaining full-spectrum extracts.

Solventless Challenges

One of the down-sides to the lack of heat is the possibility of microbial contamination, such as mold or bacteria. Quality control and sterilization processes are essential in this type of extraction.

Solventless Wins

Solventless extraction has been around for centuries, especially common in the production of hashish. With the new advancements in refinement and scalability, these solvent-free methods are once again gaining popularity.

The most popular solventless products are currently water hash (bubble hash) and rosin. Though more time-intensive in production, they are quickly becoming consumer favourites for their clean extraction and incredible flavour.

Best Uses

- Hash (bubble hash)

- Rosin

- Live Resin

- Dab

*all full-spectrum extracts

5. Terpene Extraction

Subcritical CO2

Terpene extraction can be done using subcritical CO2, and often precedes other methods of extraction. Separating the terpenes first allows extractors to process the remaining material with higher temperatures, which would otherwise damage the terpenes.

Solventless

How it Works

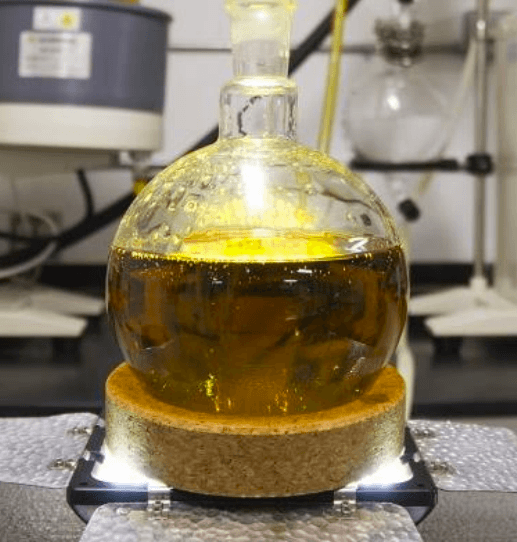

The most common method for terpene extraction is fractional distillation (aka. short path distillation). This process uses the unique boiling points of terpenes and cannabinoids for separation and collection, often in a stepwise manner.

The terpene or cannabinoid with the lowest boiling point is the first evaporate, allowing it to be condensed and collected. Then, the temperature is raised, and the next lowest boiling point compound is collected in the same way. This process is repeated until all of the components have been separated.

The Challenges

Fractional distillation is very effective for certain terpenes, but not for the smallest and most volatile monoterpenes. Certain terpenes may also have similar boiling points, and others easily undergo degradation from heat and oxygen. Again, we see here that the best method of extraction is dependent on the desired end-product.

Best Uses

- Terpenes (added back to consumer products for fragrance, flavour, and cannabinoid experience enhancement)

- Cannabinoid distillate (with up to 99% purity)

- Recombination oils (combinations of specific cannabinoids and terpenes of distinct concentrations)

The Future of Cannabis Extraction

At Valens, we are committed to pursuing excellence in extraction technology. We are working with other industry experts to standardize product testing and safety certifications, with the vision of progressing the industry to a place of consumer trust and confidence. With the ability to select for certain compounds of known therapeutic or recreational value, in specific concentrations, we believe that oil products are the future of cannabis.

There is a lot of debate in the industry about what the best method of cannabis extraction is, and a lot of confusion surrounding the best choice for specific extracts. Luckily at Valens, you don’t have to choose. Let us guide you through the process, ensuring the most economical, quality-controlled, and purposeful extracts available.

References:

- Shindell, D., Faluvegi, G., Seltzer, K., & Shindell, C. (March 2018). Quantified, localized health benefits of accelerated carbon dioxide emissions reductions. Nature Climate Change 8: 291-295.

- Universal Industrial Gases, Inc. Contributors (2016). Carbon Dioxide Properties, Uses, Applications CO2 Gas and Liquid Carbon Dioxide. Universal Industrial Gases, Inc.

- Kaupp, G. (August 1994). Reactions in Supercritical Carbon Dioxide. Angewandte Chemie 33(14):1452-1455.

- Vitalis Contributors (January 2018). Supercritical Carbon Dioxide and the Pillars of Extraction. Vitalis Extraction Technology.

- Samadzadeh, K. (December 2017). Supercritical Fluids. Chemistry LibreTexts. Physical and Theoretical Chemistry, Physical Properties of Matter, States of Matter.

- Mayfield, A. (October 2018). Sub- c. Supercritical CO2 Extraction. Extraction Magazine – Applied Technology.

- Vitalis Contributors (2019). What is CO2 Extraction. Vitalis Extraction Technology.

- Capna Labs Contributors (August 2016). Why Ethanol Extraction Works so Well for Cannabis Extraction. Leafly- Industry.

- World of Molecules Contributors (2019). Chemical and Physical Properties of the Ethanol Molecule. World of Molecules.

- U.S. Food and Drug Administration Contributors (April 2018). CFR- Code of Federal Regulations Title 21 – Part 184- Direct Food Substances Affirmed as Generally Recognized as Safe. U.S. Food & Drug Administration.

- Wells, M.J. (June 2018). Your Guide to Ethanol Extraction. Columns- Biology Brief. Cannabis Business Times.

- May, M. (May 2018). The Best Cannabis Extraction Methods for Marijuana Concentrates. Analytical Cannabis – Extraction. Science. Testing.

- Walsh, C. (2017). Butane and Live Resin Extraction System 101: CO2, Cannabis, and Terpenes Extraction Information. Terpenes and Testing Magazine.

- Wells, M.J. (May 2018). Your Guide to Hydrocarbon Extraction. Columns- Biology Brief. Cannabis Business Times.

- Sinha, S., Ricord, K., Harasym, P., Biernaskie, J., Nickerson, D., and Gabriel, V.A. (January 2018). Burns from illegal cannabis oil manufacturing: a case series. CMAJ Open 6(10):E39-E43.

- ATS Senior Editor (March 2017). C1D1 and C1D2 and the Differences. ATS ShiefSafe.

- Bennett, P. (July 2016). The Many Types of Solventless Cannabis Extracts. Leafly: cannabis 101.

- Rafael-Hawkins, O. (November 2017). What is Bubble Hash? Leaf Science.

- Marco (January 2019). What is Rosin? Exploring the Purest Cannabis Concentrate. Greencamp.

- LaBarbera, A. (November 2017). Short Path Distillation 101. Cannabis Tech.

- Chromatography Today Contributors (March 2018). A Systematic Approach to Developing Terpene Extraction Conditions Utilising Supercritical Carbon Dioxide. Chromatography Today.

- Bennett, P. (May 2017). Cannabis Oil Distillate: A Different Kind of Concentrate. Leafly: cannabis 101.

*all references retrieved on April 8th, 2019

Looking for more information on cannabis extraction? Connect with us to learn more.